|

Aero Acoustic Levitator

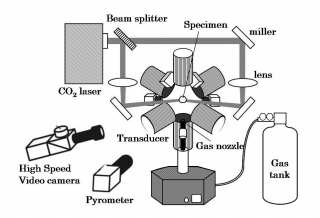

Starting from the left, Electronics Rack Assembly, CO2 laser, Water-cooled Cu hearth, Levitator Frame Assembly and Gas tank.

-Please save following movies on your desktop first, and check'em out. Don't miss it! Scanning Electron Microscope

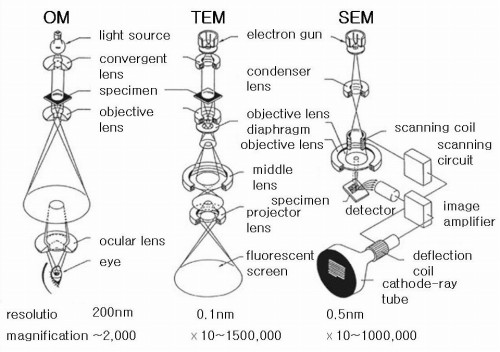

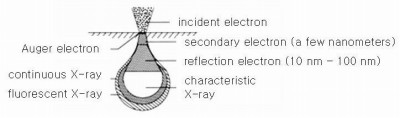

Starting from the left, SEM with EDS, Au-Pd and carbon coater and Polish station. Unlike the TEM, where electrons are detected by beam transmission, the Scanning Electron Microscope (SEM) produces images by detecting secondary electrons which are emitted from the surface due to excitation by the primary electron beam.[4] The brightness of the signal depends on the number of secondary electrons reaching the detector. The most common imaging mode of a SEM monitors low energy (<50 eV) secondary electrons. Due to their low energy, these electrons originate within a few nanometers from the surface. X-rays, which are also produced by the interaction of electrons with the sample, may also be detected in an SEM equipped for energy dispersive X-ray spectroscopy or wavelength dispersive X-ray spectroscopy. Beyond their scientific value, SEM images are actually interesting.  image by JEOL  Depth of quantum generation and spatial resolution (by Goldstein) The following are images taken using a scanning electron microscope.

SEM sample pictures X-ray Diffractometer

High Speed Video camera

Pyrometer

Vibrating Sample Magnetometer

Reference

1. Kuribayashi, K., Text for containerless solidification processing.

-Aero Acoustic Levitator: AAL

,

movie 1

,

movie 2

,

movie.mov

2. Aero-acoustic levitator operator's manual, Containerless Research,Inc. 1996 3. Weber, J.K.R., Hampton, D.S., Merkley, D.R., Ray, C.A., Zatarski, M.M. and Nordine, P.C., Rev. Sci. Instrum., 65(1994), 456-465. -X-ray Diffractometer: XRD -Scanning Electron Microscope -Vibrating Sample Magnetometer -High Speed Videocamera: movie -Pyrometer -Image furnace |

┐(- _ -;) ┌ what?